Mechanical ventilation heat recovery

Here we describe one of the defining features of a Passivhaus: the mechanical ventilation heat recovery (MVHR) system. With a high degree of both airtightness and insulation, a building needs effective ventilation. An MVHR ensures both a constant supply of 100% fresh air and the retention of 90%+ of the warmth in the house. In turn, this contributes to a high-quality indoor environment.

Why does a passive house need an MVHR system?

Two of the key features of a Passivhaus are very substantial insulation and an exceptionally high level of airtightness. This is because air leaking through a house’s insulation takes heat with it as well as creating draughts.

In a more traditionally-build house, air leakage can be good by helping to reduce condensation within the building’s fabric, albeit reliant on variable outdoor wind strength and air pressure. Older houses, especially, were ‘leaky’ (and thus draughty) and this helped to control moisture and reduced the risk of rot in the building’s fabric. But it also made them much colder and required much more energy for space heating.

High levels of insulation and draught-proofing help to retain heat, but without adequate ventilation risk moisture retention and structural damage. Many of us will have seen mildew in the colder, moister places in houses and seen condensation on the insides of window panes, and experienced draughts. You will not experience any of these in a passive house.

Controlled ‘mechanical’ ventilation prevents this potential damage in a highly insulated, near-air tight Passivhaus. And to help keep the house warm in the colder months heat is extracted from air leaving the building to warm the air coming in. This is achieved with a mechanical ventilation heat recovery (MVHR) system.

The picture on the right shows our MVHR unit. On its right side is the duct taking stale air from the house into the MVHR heat exchange unit, and on the left, covered in dense insulation, is the duct to the outside. This MVHR unit recovers at least 90% of the heat in the stale air to warm the incoming air.

Hidden from view, behind the outlet duct on the left, also heavily insulated, is the duct bringing in fresh air from outdoors into the heat exchanger. At the back on the right, just visible, is the duct taking this fresh and warmed air into the house.

Unlike an air conditioning unit which, commonly, recirculates air, a passive house is constantly refreshed with 100% fresh and filtered outside air. In the colder months it’s a bit like having windows open all the time except that the air coming in is warmed and there is no perception of draughts. (The airtightness also means there is no draught when a door is opened to let someone in or out. There is no flow of air because the building is, almost literally, leak-free.)

Importantly, in a Passivhaus Institut-certified MVHR system, you can expect that greater than 75% of the heat in the house is retained (usually much more), which is not what happens when you open a window. The Passivhaus Institut certificate for this MVHR unit states that, at an outdoor temperature of -10degC, it achieved 91% heat retention and warmed the incoming air to at least 16.5degC.

Whilst it is not necessary for all components to be Passivhaus certified to achieve the Passivhaus standard it is probably best to get a Passivhaus Institut-certified MVHR unit because not all MVHR systems are the same. A Passivhaus Institut-certified unit guarantees a minimum standard of performance.

MVHR design

Following substantial research, we concluded that – as for our window and door system – Green Building Store offered the best service for design, supply and commissioning of our MVHR system.

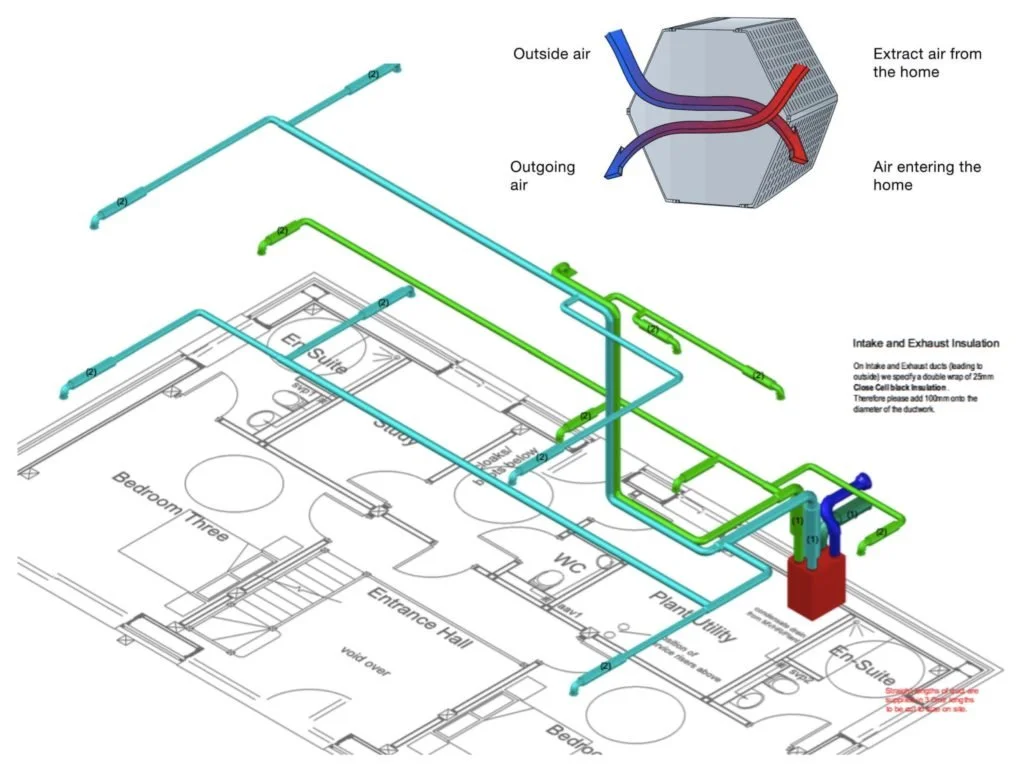

The diagram below shows an initial design for our MVHR system (the upstairs and downstairs ducts are overlaid onto the downstairs room layout). The green ducts extract air from the kitchen and en-suite bathrooms and (duct not shown here) from the downstairs WC. The turquoise ducts deliver fresh, warmed air to other living areas. The diagram inset top right depicts the heat exchange mechanism in the MVHR unit.

MVHR duct installation

The wide range of different MVHR duct systems boil down to two main options: flexible plastic and rigid galvanised metal systems. Whilst converting an existing house to the passive house standard will almost always require a flexible duct system, we considered that, for our new-build, a rigid duct system offered us the highest quality, most reliable and greatest longevity option.

The pictures above show some of the parts of our MVHR spiral rigid ducting. We chose aluminium zinc-coated steel Lindab ducting supplied by Green Building Store. This video describes the ease of installing Lindab system.

In the top left picture above you can see the ducting that was installed by our builder at the oak frame erection stage where ducts needed to be positioned in the Posijoists supporting the upstairs flooring. The top-right shows an example of these ducts connected in the ground floor ceiling space. The lower pictures show examples of these ducts upstairs. For example, bottom left, is one of the outlets (covered to keep out building dust) to provide fresh air to the living room/dining area.

The middle bottom picture shows the special kitchen extractor (with an easily-accessible fat/oil filter which is removed every three months for cleaning).

And the bottom-right picture shows the extract duct for the master bedroom en-suite bathroom (temporarily sealed to keep out building dust) and the inlet and outlet ducts passing vertically in what will be a hidden service duct between the upper and lower floors. To the rear you can see the extraction duct in the master bedroom dressing room.

All of the ducts were subsequently insulated to avoid any risk of condensation because we also installed a ‘cooler battery’, as described below. All of these ducts were subsequently covered by plaster-boarding; all that’s now visible are the inlet and extraction ducts in the ceilings.

Cooler battery

We felt confident about not being cold in winter in our Passivhaus but considered that the ongoing effects of global heating might compromise the calculations of the Passive House Planning Package in terms of overheating. We thus took the advice of our heating engineer to install a ‘cooler battery’ into the air inlet duct. This was connected to our ground-source heat pump system (used for heating the house and domestic hot water – described in a separate post).

A cooler battery, which is a bit like a car radiator, is a heat exchanger placed in-line with the air intake duct after it leaves the MVHR unit going to the rest of the house.

When it’s hot, the ‘cooler battery’ takes heat from the incoming air and transfers it to the ground via the heat pump’s ground array. This stored heat helps to replenish heat taken from the ground and can be used to help heat domestic hot water

When the indoor temperature reaches a certain limit, cold fluid is passed through this heat exchanger which passes to the heat pump ground array outside. Because this fluid is colder than the air passing through the heat exchanger heat is extracted from the air cooling the air circulated to the house.

The heat extracted is transferred to the ground outside from where it can later be used to help heat the domestic hot water or, in the coldest months, warm the house.

We used a thermocouple to measure the temperature of the duct passing air into the cooler battery and the duct on its other side passing air into the house. When operating in the hotter months we’ve found that the cooler battery reduces the temperature of the fresh air being circulated to the rooms of the house by 5-7degC. In another post we describe what is happening to the indoor house temperature compared to the outdoor temperature; it is apparent that the cooler battery is helping to keep the indoor temperature at a reasonable level when it is especially hot outside.

MVHR filters

The MVHR unit contains two filters to protect its internal workings and to prevent dust and debris from outdoors getting into the house. The picture below shows, top left, the air inlet filter and, bottom left, the outlet filter both after six months’ use. On the right is a new filter being inserted into the unit. Despite being in countryside, there is clearly a lot of dust and dirt in the outdoor air and the unit is collecting a fair amount of indoor-generated dust. We used to replace these every six months but have since been advised that they only need gentle dusting at six months and replacement nnually.

The MVHR is one of the defining features of a passive house and critical for maintaining both a high degree of indoor air quality in the house and a constantly comfortable temperature.